Automatic Batch Pre Expander EPS Expanded Polystyrene Machine

Basic Info.

| Model NO. | ESPB50/110/150 |

| Computerized | Computerized |

| Certification | CE |

| Transport Package | Container |

| Specification | ESPB-50/90/130/160 |

| Trademark | EPSOLE |

| Origin | China |

| Production Capacity | 150 Set / Year |

Product Description

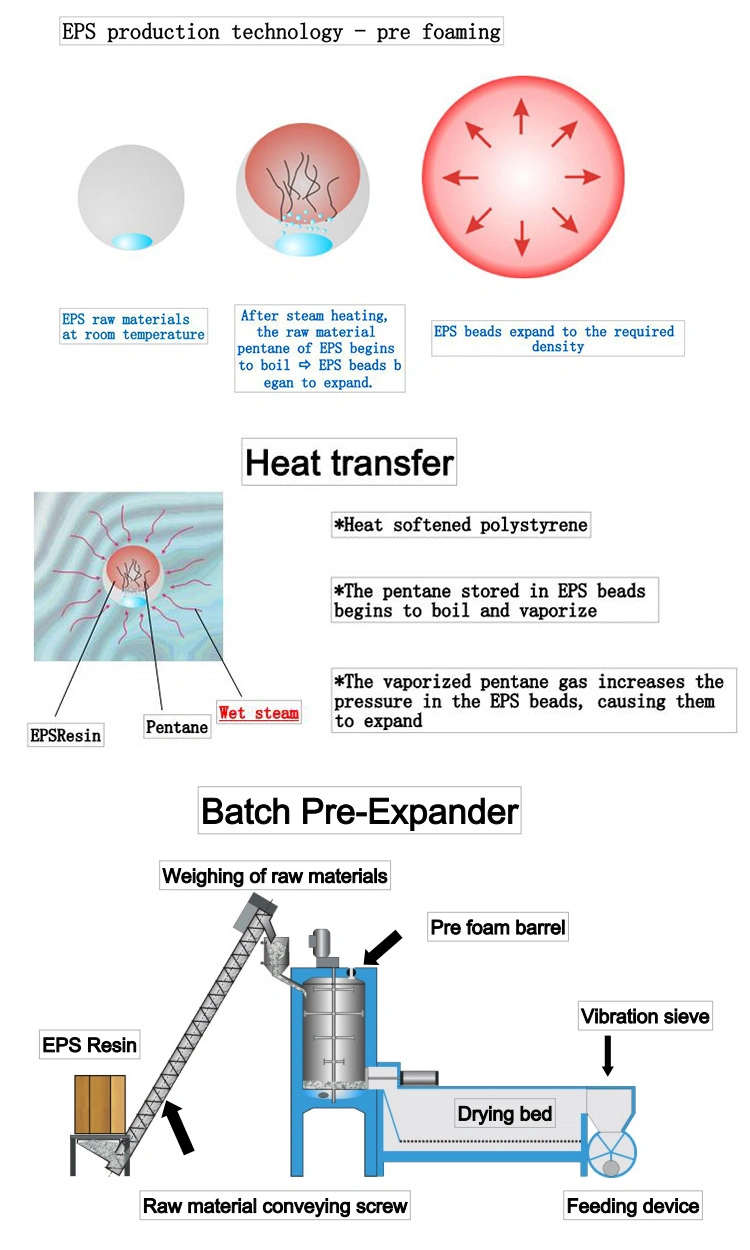

EPS Production Technology - Pre Foaming:

Batch foaming After weighing the EPS beads in batches, they enter the pre foaming machine for pre foaming. -High precision of pre foaming -Wide range of foaming density -EPS raw materials with low pentane content can be prepared -Generally, EPS raw materials contain 6-7% pentane -EPS raw materials with low pentane content contain 3-4.5% pentane (pre released in a pressurized pre foaming machine) Methods of adjusting foaming density -by adjusting the quantity of raw materials to be put in each time -by adjusting the heating time of steam -by adjusting the height of EPS beads in the foaming machine (at which point the steam is cut off) -by adjusting the steam pressure -by regulating the supply of steam (steam to air ratio) Control mode of batch foaming -Control steam pressure (0.1 to 0.6 bar) - low density -Control steam temperature (85 to 99 ° C) - high density -Air mixing - high densityFeatures

Including common dry bed,auto-feeder,screening and auto-weighing device.Steam system: controlled by relief valve and angle valveFilling system: adopt electronic weighing system,set on touch screen and the equipment is available for weighing automaticallyMaterial level control: controlled by photo sensorElectric control: with PLC&touch screen

Technical Data

| ITEM | Type | ||||||||

| ESPB-50 | ESPB-110 | ESPB-150 | ESPB-160 | ||||||

| Expansion Container | Diameter | 500mm | 1100mm | 1500mm | 1600mm | ||||

| Volume | 0.14m3 | 1.4m3 | 4.5m3 | 5.4m3 | |||||

| Useable Volume | 0.1m3 | 0.9m3 | 3.2m3 | 4.5m3 | |||||

| Steam | Entry | DN25 | DN50 | DN50 | DN100 | ||||

| Consumption | 0.5-0.7kg/cycle | 8-11kg/cycle | 15-18kg/cycle | 18-20kg/cycle | |||||

| Pressure | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa | |||||

| Compressed Air | Entry | DN20 | DN25 | DN40 | DN40 | ||||

| Consumption | 0.2-0.3m3/cycle | 0.5-0.6m3/cycle | 0.5-0.6m3/cycle | 0.5-0.8m3/cycle | |||||

| Pressure | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa | |||||

| Drainage | Drainage Port | DN80 | DN80 | DN100 | DN150 | ||||

| Condensate | DN20 | DN80 | DN40 | DN50 | |||||

| Productive Capacity | 12g/l18g/l25g/l32g/l | 70kg/h100kg/h110kg/h130kg/h | 12g/l15g/l20g/l30g/l | 240kg/h320kg/h430kg/h600kg/h | 12g/l15g/l20g/l30g/l | 600kg/h900kg/h1200kg/h1500kg/h | 12g/l15g/l18g/l25g/l | 1400kg/h1800kg/h2300kg/h2800kg/h | |

| Second expansion | |||||||||

| 8g/l10g/l | 800kg/h1000kg/h | ||||||||

| MaterialConveying Line | 150mm | 150mm | 250mm | 250mm | |||||

| Power | 9.5kw | 16.1kw | 25.85kw | 3.5kw | |||||

| Density | 12-140g/l | 12-30g/l | 12-30g/l | 12-30g/l | |||||

| Toleranoe | ≤±2% | ≤±2% | ≤±5% | ≤±5% | |||||

| Overall Dimension | (L×W×H) | 3000×3800×3800(mm) | 5600×3800×4530(mm) | 6500×4150×5400(mm) | 8600×3500×5800(mm) | ||||

| Weight | 1500kg | 3500kg | 5000kg | 8000kg | |||||

| Room Height Required | 5000mm | 5000mm | 6000mm | 7000mm | |||||

FAQ

1. Q: Where is your company located? How can I visit there?

A: Our factory is located in Hangzhou City, Zhejiang Province, China. Welcome to visit us.

2. Q. Do you have some videos where we can see the line producing?

A: Yes, we can provide some videos for reference.

3. Q: What's the MOQ?

A: Our MOQ is 1 Set.

4. Q: Can I have my own customized product?

A: Yes. Your customized requirements for color, logo, design, package, carton mark, your language manual etc. are very welcome.

5. Q: Can you produce according to the samples?

A: Yes, we can produce mold by your samples or technical drawings.

6. Q: What's the delivery time?

A: Generally, it will take 20 to 60 days after receiving your advance payment. The specific delivery time depends on the items and

the quantity of your order.

7. Q: What is the payment terms?

A: T/T, L/C, D/P at sight

8. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

9. Q: What certificate do you have?

A: We have TUV, CCC, CE (EN71, EN14765), SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.