PS EPS Bottle Flakes Recycling Machine

Basic Info.

| Model NO. | xt500-3000 |

| Weight | 20-80 Ton |

| Capacity | 300/500/1000/1500/2000kg/H |

| Blade | Wear Resistant Alloy Steel |

| Bearing | NSK, Japan |

| Hydraulic | Quick Access to Cutting Chamber, Easy for Blades M |

| Final Product | Clean PP PE Films (20-80mm) |

| Name | PP PE Film Bag Plastic Washing Line |

| Motor | Siemens Brand/Marathon |

| Color | Customer Choice |

| Transport Package | Film Package or Woodcase Package |

| Trademark | XINTING |

| Origin | Zhangjiagang Jiangsu China |

| HS Code | 8477800000 |

| Production Capacity | 300-2000kg/Hour, 1line Per Month |

Product Description

PS EPS BOTTLE flakes recycling machine

What we can offer you:

Description :

plastic cleaning machine is designed to clean recycled plastic woven sack and plastic farm film, the machine is widely used for PET,PP,PE plastic cleaning and plastic bottle cleaning. Developing on the basis of advanced technology, the machine has advantages of stable performance, high output, energy efficiency, small floor area and good appearance. We can produce the machine according to client requirement.

There are 300-2000kg/h etc capacity , we need make quotations according to your detailed requirements .

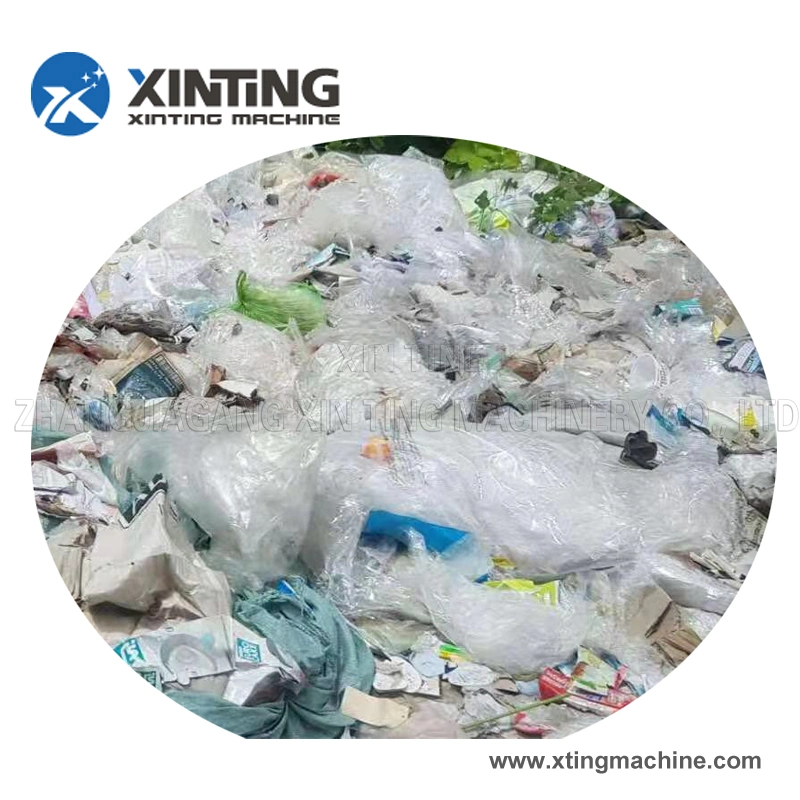

Application : Suit for recycling PP/PE waste film, Post consumer film, Food contaminated film, Garbage

film, Agricultural film, Mulching film, Greenhouse film, PP woven bags etc.

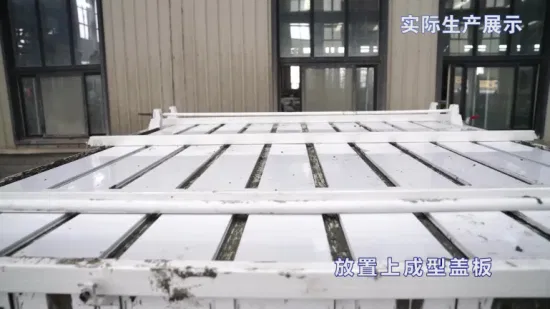

Specification : The production line is mainly composed of Plastic Film Shredder/ Plastic Film Granulator, Friction

Washer, Sink Floating Tank, Horizontal Centrifugal Dryer, Squeezer or Squeezer & Agglomerator. The whole

production line is easy to operate, efficient and low energy consumption.

Detailed parameter of Waste PP PE recycled ldpe hdpe plastic washing machine / line / plant / equipment

| Model | Capacity | Installed power | Hot washing | Water suppply | Man power | Area required |

| PE-300 | 300kg/h | 120kw | Optional | 4-5m³/h | 1-2 | 23m×5m×3.5m |

| PE-500 | 500kg/h | 185kw | Optional | 5-6m³/h | 1-2 | 25m×6m×5.5m |

| PE-1000 | 1000kg/h | 270kw | Optional | 7-8m³/h | 1-2 | 40m×6m×5.5m |

Output Type : Material will be processed by crushing, washing, dewatering, drying. The humidity of final output

could be within 5-10%.

Material will be processed by crushing, washing, dewatering, squeezing & aggregating. The

humidity of final output could be within 2%.

Product Application

Waste PP PE Film Recycling Machine is mainly suitable for crushing and washing dirty plastic film into clean film flakes,like agriculture film,packing film,shopping bags,woven bags and so on soft plastic materials.| Machine Model | Washing Capacity | Total Machine Electric Consumption | Total Machine Water Consumption(if you have dirty water treatment equipment,then water can be recycled) |

| HS-300 | 300KG/H | 80KWH | 1-2ton/hour |

| HS-500 | 500KG/H | 100KWH | 2-3ton/hour |

| HS-1000 | 1000KG/H | 160KWH | 3-4ton/hour |

After-sales Service : Our company have a experienced installation team to provide professional installation

guidance and training support.

Ability

Thanks to innovative washing technology and high quality performance. We removes the most difficult contaminants from PP/PE/PS/ABS plastic materials. Cleans post consumer film, agricultural film, Rigid bottle/drum, Battery case, WEEE plastic and even heavily contaminated woven bag fibre material. Provides almost 100% purity washing results.

Stability

We are available for 24 hours working non-stop operation. Optimized design and top brand components to each module. Which could minimize the downtime ratio and save the maintenance time. This ensures the maximum availability and highest productivity for user.

Efficiency

We are designed in all details for efficiency improving. The modular design could simplifies the planning and accelerates the implementation. The system have very low consumption values for electricity, water and chemicals. The operating costs and maintenance costs are absolutely reduced. Consistently the lowest investment costs and highest value creation!

Modularity

All elements required by any customer for different application could be combined freely. This design reduces planning, construction and assembly time effectively. And it's possible to adjust the system with regard to technological modification and market changing. This makes the investment future-proofing!

Intelligent control

Intelligent automatic module control of Xinting Machinery. One Main control panel with modern Touch Display for efficient interaction of all component. Multi-language available for operating system.

Turnkey service

XINTING is a flexible and customer-oriented recycling solution. The proposal is integrated and engineering project. Building design, overseas installation, commissioning and training are available. Machine warranty with spares in stocking and in-time delivery. Consistently quick and careful service in pre-sales and after-sales process.