Circular Economy XPS/EPS/PS Recycling Machine Waste Utilization

Basic Info.

| Transport Package | Wooden Cases |

| Specification | Single screw |

| Trademark | Feininger |

| Origin | Nanjing, China |

| HS Code | 84774020 |

Product Description

EPS Recycling Machine/XPS Recycling MachineXPS Recycling Machine for EPS Waste and XPS Foam Production

1.EPS Recycling System

The recycled EPS products are compressed into regular large blocks, which are convenient for stacking and transportation, and then crushed into small particles, which are directly added to the granulator to form XPS granules, which are used in the production of XPS products, realizing 100% cyclic production.

2.XPS Powder Recycle Machine

In XPS production there about 10% XPS offcut powder on line as the waste, which can be collected o one big silo, then be transported to our recycling system. The recycling system consists of two extruders (primary extruder and secondary extruder), screen changer, slot die and pelletizer.

Main technical parameters

Brief description: Recycle the XPS/EPS powder into GPPS granules.

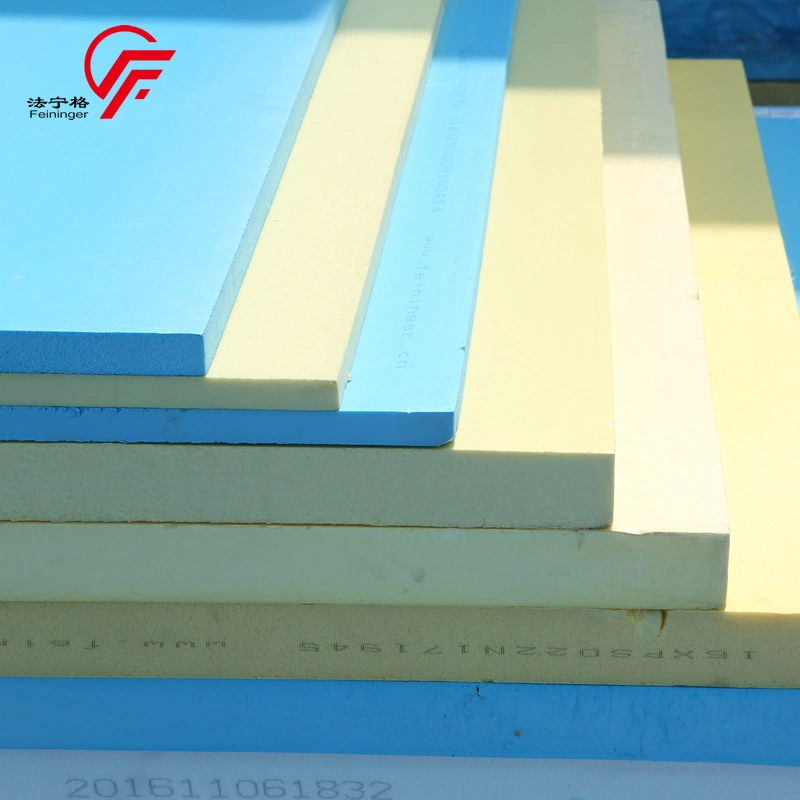

Our machine can use both recycled EPS materials and recycled XPS material to produce XPS insulation board,Achieve 100% recycling,these prodcuts are all made by recycled materials.

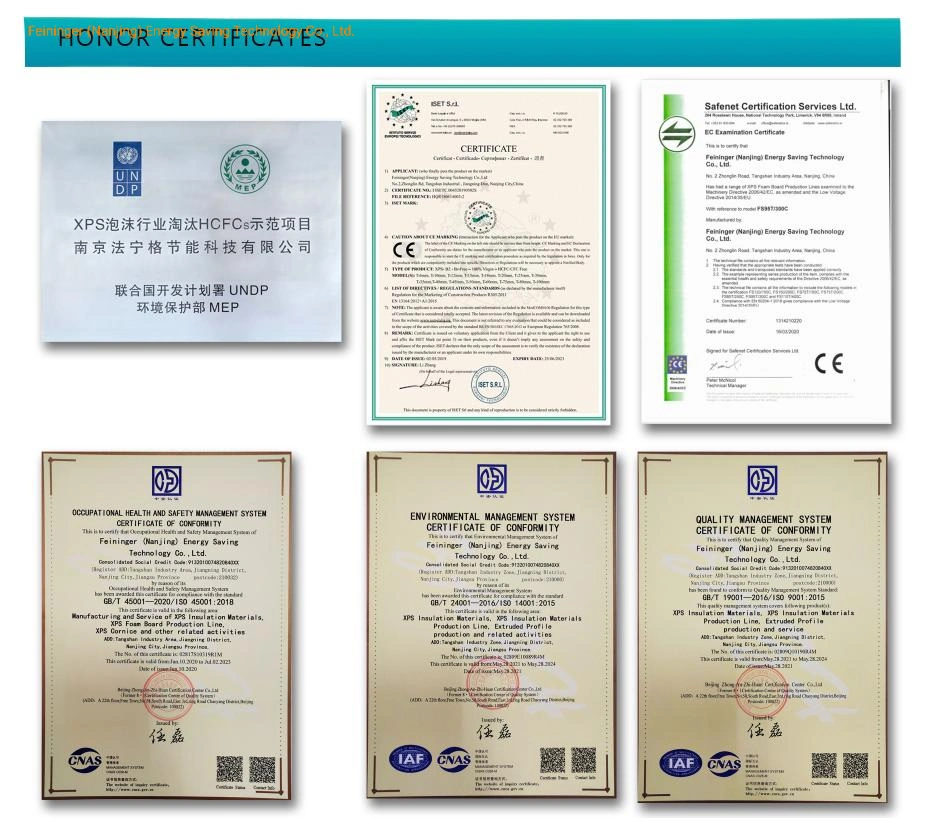

Feininger has been engaged in foam extrusion technology and its industrialization for more than 18 years. We are located in China with the globalview. Feininger had been passed ISO:9001 and CE certificates which guaranteed our products to have higher quality requirements and more caring designs. Nowadays, Feininger becomes the leading supplier for both XPS board extrusion line and XPS insulation board all over the world.

Packaging & Shipping

Packing Way of XPS Foam Board Production Line with CE/ ISO;Wood Pallet for Main Extruders;Wooden Case for other parts;Container Loading;Sea-worthy.

Company Profile

1. who are we?

We are based in Jiangsu, China, start from 2003,sell to Eastern Asia(60.00%),Mid East(20.00%),South Asia(10.00%),Africa(10.00%). There are total about 201-300 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. what can you buy from us?

XPS Production Line, XPS Foam Board,PET Extrusion Line,PS Skirting Board Production line,PS Photo Frame Extrusion Production Line

4. why should you buy from us not from other suppliers?

In the year of 2002, Feininger firstly designed and manufactured high quality XPS Foam Board Production Line in China. Since then we have contributed us to research of XPS technology improving continuously product quality.

5. what services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW;

Accepted Payment Currency: USD, EUR, CNY;

Accepted Payment Type: T/T, L/C;

Language Spoken: English, Chinese ,Russian